How an Optical Fibre Diameter Analyser Enhances Top Quality Control in Fibre Manufacturing

The combination of an Optical Fibre Diameter Analyser into Fibre manufacturing processes represents a considerable advancement in high quality control techniques. By offering real-time, specific measurements of Fibre diameters, this modern technology addresses the vital demand for uniformity in manufacturing standards.

Relevance of Fibre Diameter Dimension

Precise dimension of Fibre Diameter is important in the area of optical Fibre innovation, as it directly influences the performance and reliability of Fibre optic systems. The Diameter of an optical Fibre impacts its light-carrying capability, attenuation, and general transmission efficiency. Precision in measuring Fibre Diameter makes sure that the optical residential properties are maintained within specified resistances, which is essential for optimum signal stability.

Variations in Fibre Diameter can cause boosted losses because of scattering and modal diffusion, influencing the high quality of data transmission. In high-speed communication systems, such discrepancies can cause considerable deterioration of signal quality, leading to information errors and reduced efficiency. Constant Fibre Diameter is vital for compatibility with connectors and splicing modern technologies, which are important parts of Fibre optic networks.

Quality control procedures in Fibre manufacturing heavily rely on precise Diameter dimensions to ensure conformity with industry criteria. By carrying out robust dimension methods, manufacturers can boost product integrity, minimize waste, and boost general system performance. Thus, the value of Fibre Diameter measurement can not be overstated, as it works as a cornerstone in the improvement of optical Fibre innovation and its applications in contemporary communication networks.

How the Analyser Works

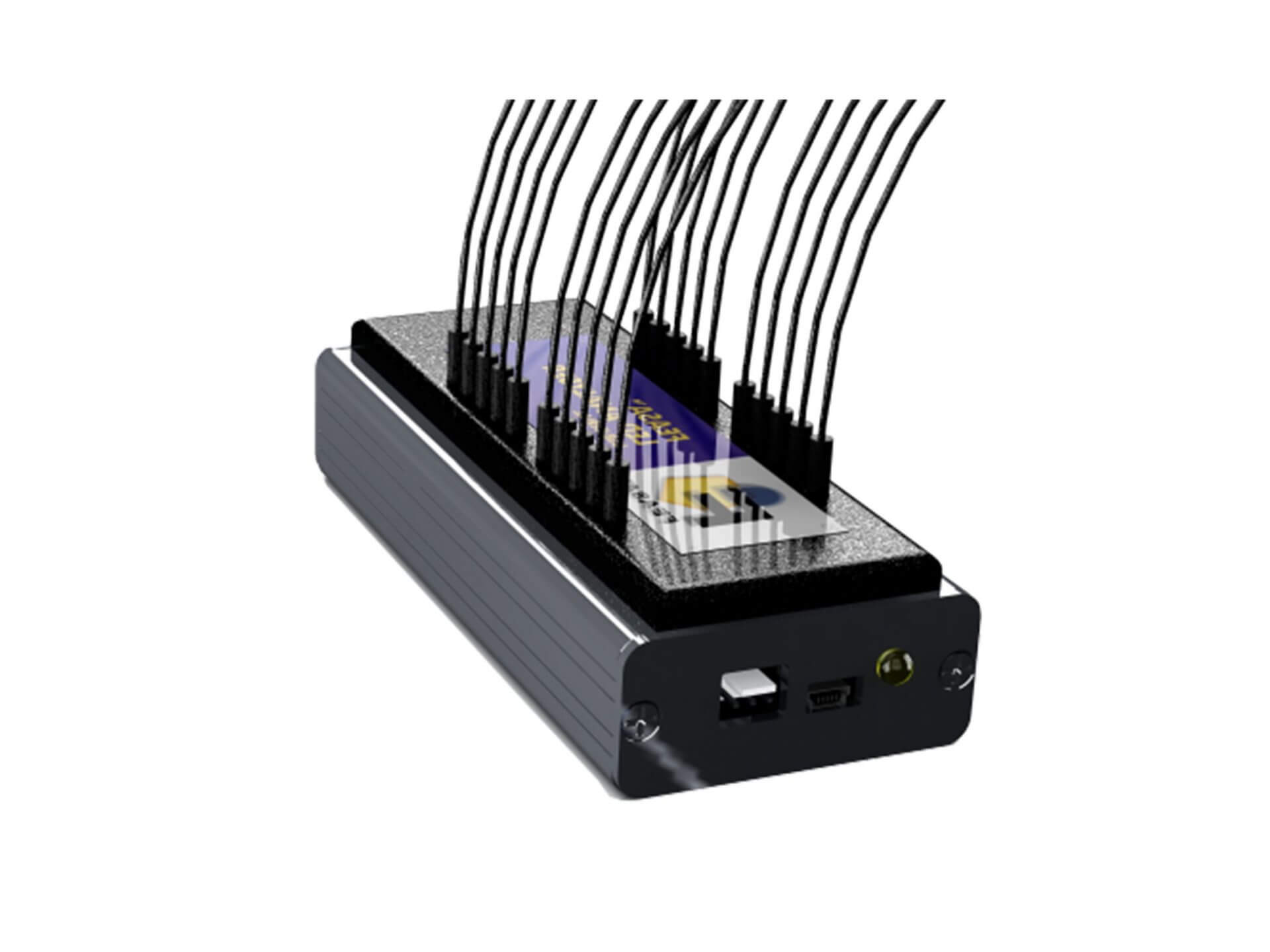

The effective measurement of Fibre Diameter relies upon innovative logical strategies that make certain precision and dependability in optical Fibre manufacturing (optical fibre diameter analyser). The Optical Fibre Diameter Analyser utilizes a mix of laser technology and progressed picture handling algorithms to accurately assess the Diameter of fibers as they are produced

Originally, a laser beam is directed at the relocating Fibre, developing a cross-sectional darkness. The analyser catches this darkness making use of high-resolution electronic cameras positioned strategically along the manufacturing line. The captured pictures are after that processed in real-time to establish the Fibre's Diameter with phenomenal accuracy.

The system utilizes advanced algorithms that represent different variables, consisting of variants in light strength and ecological problems, to boost dimension reliability. It can spot minute modifications in Diameter, such as changes that may happen during the manufacturing process.

In addition, the analyser can taking care of numerous fibers concurrently, boosting throughput without jeopardizing accuracy. By offering instant feedback on the Diameter, the Optical Fibre Diameter Analyser plays a crucial role in keeping rigid quality assurance standards, guaranteeing that the end product fulfills market specifications and customer needs.

Benefits of Real-Time Monitoring

While typical techniques of keeping track of Fibre Diameter often entail lengthy post-production checks, real-time monitoring significantly improves the efficiency and top quality of optical Fibre production. optical fibre diameter analyser. This positive technique enables manufacturers to determine deviations in Fibre Diameter as they happen, rather than waiting up until production is total to assess high quality

By continually determining the Diameter during manufacturing, producers can make you could try these out certain that the fibres satisfy stringent specs, leading to minimized irregularity and improved uniformity. Real-time monitoring likewise makes it possible for immediate restorative activities to be taken, reducing waste and protecting against defective fibres from entering the supply chain.

Moreover, this technology facilitates boosted data collection and evaluation, giving insights into manufacturing fads and potential areas for renovation. Such data-driven decision-making encourages producers to enhance procedures and keep high standards of quality control.

Additionally, real-time surveillance cultivates a society of continual improvement within the production environment. Workers are a lot more involved when they can see the influence of their job in real-time, leading to heightened responsibility and a dedication to excellence. In general, the application of real-time tracking systems in optical Fibre manufacturing equates to remarkable product high quality and boosted client contentment.

Effect On Manufacturing Effectiveness

Carrying out optical Fibre Diameter analysers substantially improves production effectiveness by improving the manufacturing process. These devices promote continual surveillance of Fibre Diameter, allowing manufacturers to spot deviations in real-time. By identifying incongruities without delay, assembly line can be changed quickly, decreasing downtime and minimizing the probability of creating defective items.

In addition, the combination of these analysers into the manufacturing operations allows better source allowance. With accurate Diameter dimensions, operators can maximize material use, making certain that sources are not squandered on flawed fibers. This precision additionally contributes to much less remodel and scrap, eventually lowering production prices.

The automation supplied by optical Fibre Diameter analysers reduces dependence on manual assessments, which are commonly time-consuming and susceptible to human mistake. Because of this, workers can concentrate on more critical tasks, improving overall efficiency.

In addition, the data created from these analysers can notify procedure improvements and assist in far better decision-making. By evaluating fads in Fibre Diameter variations, makers can execute proactive procedures to boost production methods and keep consistent quality. In recap, optical Fibre Diameter analysers play an important duty in improving manufacturing efficiency, resulting he has a good point in greater top quality output and enhanced earnings.

Instance Researches and Success Stories

Across various industries, study highlight the transformative impact of optical Fibre Diameter analysers on production processes. One popular instance is a leading telecoms firm that encountered obstacles with irregular Fibre sizes, causing increased rejection rates. By integrating an optical Fibre Diameter analyser, the company achieved real-time monitoring of Fibre dimensions, causing a 30% decrease in issues and substantial price financial savings.

Additionally, a research organization focusing on sophisticated products used optical Fibre Diameter analysers to improve their experimental procedures. The analyser's capability to give comprehensive understandings into Fibre consistency made it possible for the growth of innovative products with improved efficiency characteristics.

These success stories emphasize the vital browse around these guys function of optical Fibre Diameter analysers in improving quality control, boosting production effectiveness, and driving innovation across varied industries.

Final Thought

In final thought, the Optical Fibre Diameter Analyser plays a crucial duty in boosting high quality control within Fibre production. As demonstrated via numerous instance researches, the analyser proves important for accomplishing exceptional product quality in Fibre production.

The application of optical Fibre Diameter analysers permitted for rigid quality control, making sure that the produced fibers met exacting market standards.In final thought, the Optical Fibre Diameter Analyser plays a crucial role in boosting quality control within Fibre manufacturing.

Comments on “The Efficiency of an Optical Fibre Diameter Analyser in Reducing Manufacturing Errors”